Answer these simple questions and we will find you the BEST prices

Which type of solar quotes do you need?

It only takes 30 seconds

100% free with no obligation

Tell us what you need to find a matching specialist

Get free quotes from professionals near you

Compare offers and choose the one that best matches your need

- whatcost.co.uk

- Home Insulation

- Blown Insulation

Blown Insulation: Pros, Cons, Types & Costs

- Blown insulation is a method of applying loose material fibres by blowing them into spaces such as lofts and cavity walls using industry-specific equipment.

- The most popular blown insulation materials are cellulose, mineral wool, and fibreglass.

- Loose-fill insulation materials can cost around £10 - £18 per m2, depending on your chosen material.

Rising energy bills are a major concern for UK homeowners. One of the most effective ways to combat these costs is to improve your home's energy efficiency with home insulation. Blown fibre insulation is a popular and versatile solution that can significantly reduce heat loss. This method utilises loose-fill materials like cellulose, mineral wool, or fibreglass, which are carefully blown into hard-to-reach areas such as lofts, cavity walls, and stud walls.

By effectively filling gaps and voids, blown-in insulation can dramatically reduce your energy consumption and lower your heating bills. This article will explore the benefits, considerations, and suitability of blown-in insulation for your home.

This complete guide by WhatCost will give you everything you need to know about blown insulation, including pros, cons, material types, costs, and insulation grants.

Ready to insulate your home? Let WhatCost land you the best bargains. Spend just 30 seconds filling out our online form and receive up to 3 free home-tailored quotes from our nationwide network of trusted installers. No costs, no obligations. Simply click below to begin!

What is blown insulation and how does it work?

Blown-in insulation is a method where loose-fill materials like mineral wool, fibreglass, or cellulose are injected as blown cavity insulation or loft insulation using specialised equipment. This technique offers a convenient and effective way to upgrade insulation in various areas of your home on a budget.

The typical process of installing blow-in insulation is as follows:

- Preparation: Before installation, the area is thoroughly prepared. This involves removing debris, sealing any gaps or cracks to prevent moisture intrusion, and ensuring the space is dry. An installer may also have to do some outstanding repair work.

- Installation: A professional installer then uses specialised equipment to blow the insulation material into the designated area. For cavity walls, small holes are drilled in the outer wall to access the cavity space. For non-use lofts and attics, a hose is used to spray insulation directly into the space.

- Completion: Once the insulation is in place, the area is carefully sealed to protect it from moisture and weather damage. For cavity walls, the drilled holes are sealed with cement for a seamless finish.

Blown-in insulation is a quick, sustainable and relatively inexpensive method of insulation. To ensure long-lasting benefits, it's crucial to work with an accredited installer who can deliver high-quality workmanship and maximise the energy efficiency of your home.

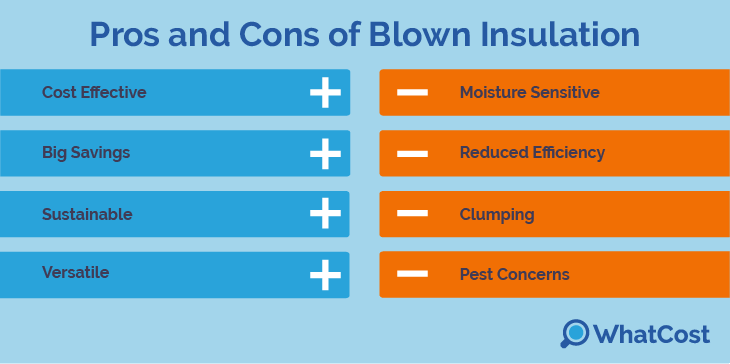

Pros and cons of blown in insulation

Blown-in insulation offers a compelling solution for enhancing your home's energy efficiency and comfort on a budget. Amongst several advantages, here's why it's a top contender:

- Cost-effective: Loose-fill materials like fibreglass, cellulose, and mineral wool are generally more budget-friendly than some other insulation options. They’re also easier to install and remove, saving you money on professional work.

- Big savings: Blown-in insulation effectively reduces heat loss, leading to noticeable decreases in your energy bills. For example, cavity wall insulation in a detached house can potentially save you up to £370 every year.

- Sustainable: Many blown-in insulation materials are made from sustainable and recycled sources. Cellulose, for instance, is primarily composed of recycled paper and wood products, while mineral wool and fibreglass are easily recyclable.

- Versatile: Blown-in insulation excels at filling hard-to-reach spaces, such as attics with limited access, or awkward shapes and crevices of roof structures.

Overall, blown-in insulation presents a highly effective and budget-conscious option for improving your home's energy efficiency and comfort, however, it’s just as important to address the disadvantages one may face with blown-in insulation. Let’s have a look at the key cons:

- Moisture sensitive: Some materials, such as cellulose, can be more susceptible to moisture absorption. This can lead to mould and mildew growth, reducing the insulation's effectiveness. Adequate ventilation and airtightness are crucial to prevent this.

- Reduced efficiency: Moisture exposure can degrade the insulating properties of loose-fill materials. This may require drying or even replacement of the insulation.

- Clumping: Over time, loose-fill insulation may settle and clump, creating gaps and reducing its effectiveness. Regular top-ups can help maintain even distribution.

- Pest concerns: If not properly sealed, blown insulation can provide nesting sites for insects and pests. This can compromise performance and introduce unwanted guests.

While DIY installation is tempting, it's crucial to hire a qualified professional. Proper installation will minimise these potential drawbacks, ensuring long-term performance and energy savings.

Types of blown in insulation

Blown-in insulation is a popular choice for enhancing home energy efficiency. It involves installing insulation materials using specialised equipment that blows material into the desired space. Common materials used for blown-in insulation include:

- Cellulose: Manufactured from recycled paper and wood products, blown cellulose insulation is an eco-friendly and cost-effective option. It can be used in lofts, cavity wall insulation, and behind internal stud walls. However, it's susceptible to moisture and may settle over time, potentially creating gaps in insulation.

- Fibreglass: Made from tiny glass fibres, blown-in fibreglass offers good heat retention and is flame-resistant. It's commonly used in attics, particularly those not intended for living space. However, handling fibreglass requires caution as it can irritate the skin and respiratory system.

- Mineral wool: Manufactured from rock or glass, mineral wool provides excellent thermal insulation and is naturally moisture-resistant. Rockwool blown insulation is also fire-resistant and can offer some soundproofing benefits. Like fibreglass, blown rockwool insulation can irritate, and must be handled with protective gear, but makes great insulation for loft purposes.

- EPS polystyrene: This bead cavity wall insulation is made from polystyrene polymer and is not very suitable for loft insulation. Nevertheless, these blown in beads pack superior qualities such as thermal performance, durability, and resistance to moisture, mould, and flames. Insulation beads are also relatively budget-friendly.

What is the best blown-in insulation?

There's no single best insulation and selecting the ideal blow in insulation involves considering factors like your budget, specific insulation needs, existing insulation, and personal preferences.

When prioritising thermal performance while remaining budget-conscious, fibreglass insulation emerges as a top contender. It's affordable and effective, making it a popular choice. Furthermore, fibreglass boasts strong sustainability credentials, being made from repurposed glass and easily recyclable.

Beyond thermal efficiency, fibreglass enhances safety. It is non-flammable, an excellent electrical insulator, and free from harmful chemical releases. These qualities contribute to its long-term reliability and safety for jobs such as blown cavity wall insulation.

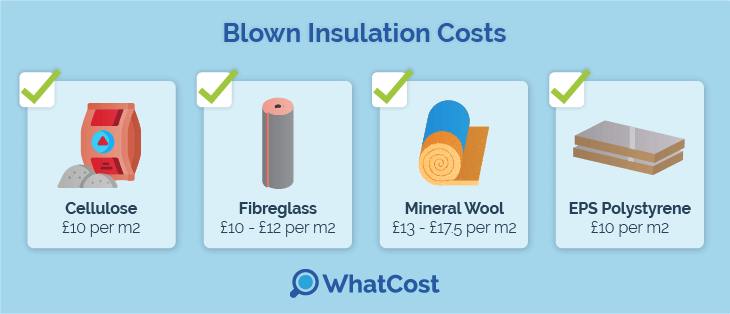

Blown insulation cost

Blow in insulation is generally a cost-effective insulation method, with materials costing around £10 - £18 per m2. While the exact blown insulation cost can vary depending on factors like the type of material used, the size of the space, and the complexity of the installation, loose-fill insulation materials are typically more budget-friendly than their market alternatives.

Here’s a breakdown of the expected cost of insulation material per m2:

| Insulation material | Cost per m2 |

|---|---|

| Fibreglass | £10 |

| Cellulose | £10 - £12 |

| Mineral wool | £13 - £17.5 |

| EPS polystyrene | £10 |

Choosing the best-fit material for your insulation needs is important, but so is choosing the right professional insulation companies. With the sea of options available these days, it can be a daunting task to sift through endless quote prices. Luckily, WhatCost can streamline this process for you.

Instead of spending endless hours online and on phone calls, just spend 30 seconds filling out our online form. In return, we’ll send you up to 3 free home-tailored quotes directly from our network of pre-vetted professionals. No costs or obligations apply. Simply click below to begin!

FAQ

Blown-in insulation is a worthy investment in terms of cost-effectiveness. This is especially true if you are insulating an uninhabited loft or cavity walls, meaning your insulation will not get in the way of your livelihood.

The common disadvantages of blown-in insulation relate to its effectiveness. Blown insulation often falls into risk of clumping or leeching moisture, creating cold spots and drastically reducing its thermal efficiency. Blown insulation that has been compromised will almost always require replacing, adding to your costs.

Blown insulation does not cause dampness, but a poor installation can create the risk of moisture. To ensure dampness is avoided, a professional installer must create adequate ventilation, as well as make sure any gaps and crevices are properly sealed.

The best choice rests on your needs, for example, if you have an inaccessible loft, then blown-in attic insulation reigns supreme. If you intend to use your loft space for storage or living quarters, then rolled insulation is your best option. Consult with a professional installer who can guide you.

Akif has a keen interest in green home improvement solutions and the role of digital media in identifying climate trends. He aims to provide a multidisciplinary approach to content rooted in credible research and accuracy.